Bryce C

DFW

- Joined

- Feb 9, 2024

- Messages

- 1,210

- Name

- Bryce

Does this sound like a pulley about to go bad?

Squealing belts are almost eighter loose belts, badly worn belts . But more often than not its caused by misaligned belts. Especially if there is little or no vibration. Check idler pulleys but my moneys on alignment or loose belts

One other thought is contaminated belts. If you have been doing alat of work around them perhaps you got some grease or other products on themSquealing belts are almost eighter loose belts, badly worn belts . But more often than not its caused by misaligned belts. Especially if there is little or no vibration. Check idler pulleys but my moneys on alignment or loose belts

If the belts are misaligned the vSquealing belts are almost eighter loose belts, badly worn belts . But more often than not its caused by misaligned belts. Especially if there is little or no vibration. Check idler pulleys but my moneys on alignment or loose belts

I found over the years that if you want to be heard best then to talk to yourself ,im a carpet cleaner and pretty good with a wrench computers not so muchYou’ve started talking to yourself again Dwain

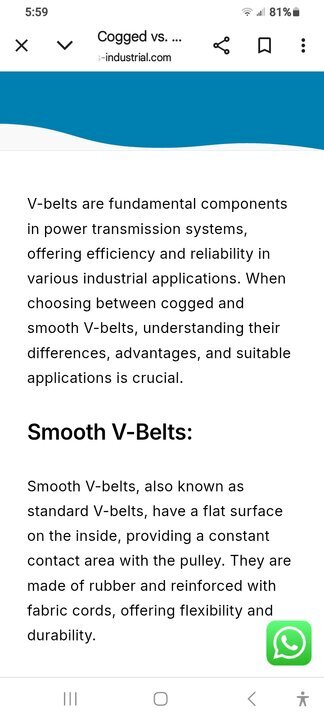

It was pointed out to me that while trying to relay more information to you i actually replied to myself. So if you scroll through the comments youll see what i was saying about belt alignment. Now the information i would like to convey is belt type. If you replace your belts and have smooth v belts change over to cogged belts i screen shot an article explaining the differences. X in gates belt # denotes cogged belt ie: Ax32 is A belt cogged 32" also if not already installed when you change your Serpentine belt upgrade to gates fleet runner belt (green belt) it holds up longer and can transfer more power than standard beltsI bought a mechanics stethoscope for identifying these things a while ago. Never used it. I suppose now would be a good time to try...

Jimmy Ladwig (may he rest in peace) told me early on in my direct drive experience to use gates green belts.

One other thought is contaminated belts. If you have been doing alat of work around them perhaps you got some grease or other products on them

Or just use a piece of stringIf the belts are misaligned the v

Belts can be straight edged aligned pretty easily. I cut down a 3' metal ruler i got from harbor freight to the various sizes of straight edges i needed for my machine. However if it is the Serpentine belt that needs to be aligned it can .be straight edged buuuuuuttt, i highly highly highly recommend that if thats the case you invest in a laser alignment tool. Serpentine belts have a tolerance of only ½ngroove for every 6" between the closest pulley and the pulley your trying to align v belts on the other hand are alot more forgiving. Lif your interested in a laser alignment tool for v belts. I found and bought one off a hog farm supply for about 30 bucks but it only works on A belts not B belts. If you want it message me and ill get you the information.

View attachment 131581

NoLadwig passed?

I replace my idler pulley every time I replace my belts. I also pack it with hi temperature grease.

There isn't an idler pulley on this machine. The drive shaft has 1 pulley in front of the blower that turns the water pump, and another pulley behind the blower that turns the blower. So 2 belts and 4 pulleys in total.Sounds like a bearing gone dry in your idler pulley.

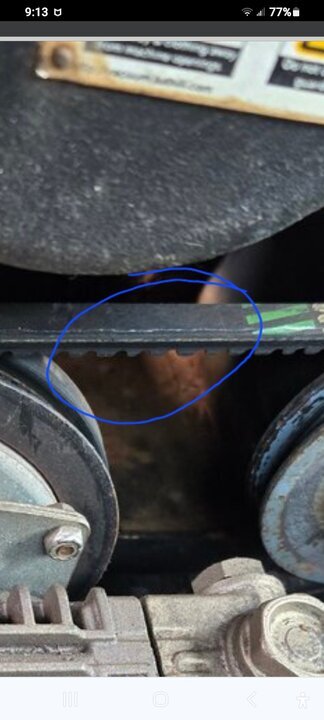

What caused this in this belt?There isn't an idler pulley on this machine. The drive shaft has 1 pulley in front of the blower that turns the water pump, and another pulley behind the blower that turns the blower. So 2 belts and 4 pulleys in total.

I can't see any wear on the belts. The belt that powers the blower feels really loose compared to the one that powers the water pump. I don't see where these pulleys can be adjusted in or out for alignment, unless the whole blower is moved to do that...

View attachment 131603

View attachment 131604

so who performed the last rites?No

He’s just dead on MB

Larry or Chavezso who performed the last rites?

If you haven't already maybe download a owners manual also theres a few long youtube videos on maintenance

View attachment 131608 View attachment 131609

Larry or Chavez

I’m just naturally pissy